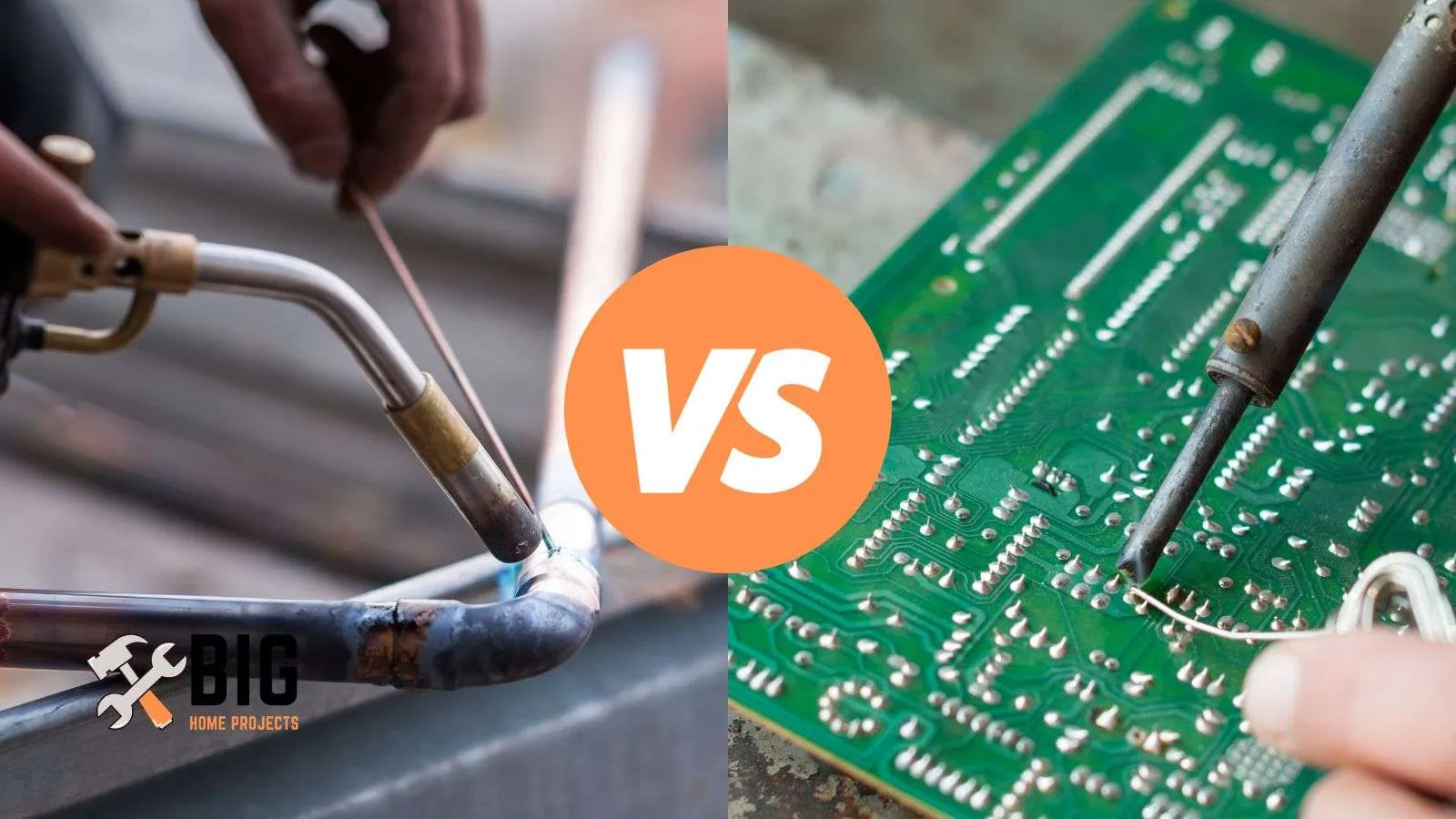

Have you ever wondered if plumbing flux and electric flux are the same thing? While both are essential components in their respective fields, they serve different purposes and have unique characteristics.

In this article, we’ll explore the differences between these two types of flux, their applications, and how to choose the right one for your project.

Is plumbing flux the same as electric flux?

No, plumbing flux is not the same as electric flux paste. While both serve the purpose of aiding in soldering, they are formulated for different applications.

Plumbing flux, used in plumbing projects, helps create a clean surface and a solid bond between solder and copper pipes or fittings.

Electric flux paste, designed for soldering electrical components and circuit boards, facilitates solder flow, enhances wetting, and ensures a reliable electrical connection.

It’s recommended to choose the appropriate flux based on the specific task at hand, whether it involves plumbing or electronics, to achieve the best results.

What are plumbing flux and electric flux paste made of?

Plumbing flux

Plumbing flux, also known as soldering flux or plumbing soldering paste, generally contains chemicals that aid in the soldering process for plumbing applications. The common ingredients found in plumbing flux can include:

- Zinc chloride: This chemical helps remove oxides and impurities from the metal surfaces being soldered, ensuring a clean and solid bond.

- Ammonium chloride: Another common ingredient, ammonium chloride, assists in the removal of oxides and promotes the flow of solder.

- Rosin: In some cases, plumbing flux may contain rosin, a natural resin obtained from pine trees. Rosin helps improve solder flow and wetting.

Electric flux paste

Electric flux paste, also known as soldering paste or electronic flux, is specifically designed for soldering electronic components and circuit boards. The typical composition of electric flux paste includes:

- Rosin: Rosin is a common ingredient in electric flux paste as well. It helps improve the wetting ability of solder, ensuring proper adhesion and electrical conductivity.

- Solvents: Electric flux paste usually contains solvents such as alcohols or hydrocarbons to aid in the application and evaporation process. These solvents help dissolve the rosin and facilitate the flux’s spreadability.

What are the main differences between plumbing and electric flux paste and their uses?

Composition

Plumbing flux paste is typically formulated with chemicals such as zinc chloride or ammonium chloride, which help clean and prepare copper surfaces for soldering.

It may also contain other additives to improve adhesion and flux performance.

Electrical flux paste, on the other hand, is generally made of rosin or other mild flux agents that are suitable for electronics applications.

The composition of electrical flux paste is designed to minimize residue and ensure compatibility with delicate electronic components.

Purpose

Plumbing flux paste is primarily used in plumbing applications to facilitate the soldering of copper pipes, joints, and fittings.

It helps remove oxidation, dirt, and other contaminants, ensuring a strong bond between the solder and the copper surfaces.

Electrical flux paste, on the other hand, is used in electronics soldering.

It aids in the wetting and flow of solder, enhancing the solder joint quality and reliability of electrical connections.

Specific applications

Plumbing flux paste is applied to copper pipes and fittings to prepare them for soldering, creating leak-free connections in plumbing systems.

People who are working on plumbing projects and plumbers both use it.

Electrical flux paste is used in electronics assembly and soldering.

It is applied to electrical connections, circuit boards, or components to facilitate the soldering process and ensure reliable electrical connections.

How do you choose between using plumber’s flux or electric flux paste?

Plumber’s flux is the ideal choice for plumbing projects that involve soldering copper pipes and fittings.

It helps create a clean surface free from impurities, ensuring a solid bond between the solder and the metal.

On the other hand, electric flux paste is specifically formulated for soldering electrical components and circuit boards.

It aids in the flow of solder, enhances wetting, and removes oxidation, guaranteeing a reliable electrical connection.

By understanding the intended uses of each flux, you can make an informed decision based on whether your project involves plumbing or electronics.

In summary, the choice between plumber’s flux and electric flux paste ultimately depends on the nature of your project.

If you’re working on plumbing tasks such as soldering copper pipes, opt for plumber’s flux.

However, if your project involves soldering electronic components onto circuit boards or repairing electronic devices, electric flux paste is a suitable choice.

What type of soldering tool should be used with plumbing and electric flux paste?

- Plumbing soldering: For plumbing soldering, a propane or butane torch is commonly used as the heat source. These torches provide a high heat output necessary to solder copper pipes and fittings effectively. The torch flame heats the joint and the solder, allowing it to flow and create a secure bond. A soldering iron or gun is generally not suitable for plumbing soldering due to the higher heat requirements.

- Electrical soldering: Electrical soldering involves working with smaller components, delicate circuit boards, and wires. The following tools are commonly used for electrical soldering:

- Soldering iron: A soldering iron is the primary tool for electrical soldering. It consists of a heated metal tip that melts the solder, allowing it to bond to the electrical components or wires. Soldering irons come in various wattages, and the selection depends on the size and complexity of the soldering job.

- Soldering station: A soldering station provides a controlled temperature for the soldering iron, ensuring consistent and reliable heat. It usually includes features like adjustable temperature settings, interchangeable tips, and a stand for holding the iron when not in use.

- Soldering gun: A soldering gun is an alternative to the soldering iron. It is a self-contained unit that generates heat and has a trigger-operated mechanism. Soldering guns are typically used for heavier electrical connections or in situations where quick heating is required.

Can plumbing flux be used for electronic soldering?

Plumbing flux is not recommended for electronic soldering. While plumbing flux and electronics flux may appear similar, they are formulated differently and serve distinct purposes.

Plumbing fluxes are designed for soldering copper pipes in plumbing applications and often contain aggressive chemicals like zinc chloride or ammonium chloride.

These chemicals can be corrosive and leave residue that can damage delicate electronic components.

Also, plumbing fluxes are not intended for the precise and controlled soldering required in electronics.

For electronics soldering, it is crucial to use flux specifically designed for electronics.

Electronic flux pastes are formulated to be less aggressive, leaving minimal residue and offering better compatibility with sensitive electronic components. They typically contain rosin or other mild flux agents suitable for electronics applications.

Using plumbing flux for electronics soldering can result in poor solder joints, component damage, or long-term reliability issues.

To ensure proper soldering and protect your electronic devices, it is recommended to use flux specifically designed for electronic soldering.

What types of flux are typically used for plumbing?

- Acid flux: Acid fluxes, such as those containing zinc chloride or ammonium chloride, are commonly used in plumbing. These fluxes are highly effective at cleaning and preparing copper surfaces for soldering. They help remove oxidation, dirt, and other contaminants, ensuring a proper bond between the solder and the copper pipes.

- Water-soluble flux: Water-soluble fluxes are also used in plumbing. These fluxes are formulated to be water-soluble, making it easier to clean the soldered joints after the soldering process is complete. They are less aggressive than acid fluxes and are suitable for applications where residue removal is important.

- No-clean flux: No-clean fluxes have gained popularity in plumbing applications due to their convenience. These fluxes leave minimal residue after soldering and do not require extensive cleaning. They are formulated to be less corrosive and can be a good option for certain plumbing applications where residue removal is not critical.

Can I use electric flux on plumbing?

Using electric flux paste on plumbing is not recommended for several reasons.

First, electric flux paste and plumbing flux have different chemical compositions that are specifically tailored for their respective applications.

Electric flux paste typically contains rosin and solvents, which may not be ideal or appropriate for plumbing soldering.

The chemicals found in plumbing flux, such as zinc chloride or ammonium chloride, play a crucial role in cleaning the surfaces and creating a strong bond between solder and copper, which may not be achieved with electric flux paste.

Moreover, plumbing flux is formulated to withstand the conditions and stresses encountered in plumbing systems, ensuring long-lasting and reliable connections.

Electric flux paste, on the other hand, may not offer the same level of durability and may not hold up well in plumbing applications.

Using electric flux paste in plumbing could potentially lead to leaks or failures over time, compromising the integrity of the plumbing system.

To ensure proper and reliable results, it is strongly recommended to use the appropriate flux specifically designed for plumbing when soldering copper pipes and fittings.

What could happen if you used electric flux paste on plumbing?

- Inadequate cleaning: Electric flux paste is not formulated to effectively clean copper pipes and fittings in the same way that plumbing flux does. As a result, the surfaces may not be properly prepared for soldering. Without thorough cleaning, oxides, dirt, and other contaminants may remain on the surfaces, preventing a solid bond between the solder and the metal.

- Weak or unreliable bonds: Electric flux paste may not provide the same bonding capabilities as plumbing flux. Plumbing flux contains specific chemicals, such as zinc chloride or ammonium chloride, which aid in the soldering process by promoting adhesion and creating a strong bond. Without the proper bonding properties, the solder joint may be weak, leading to leaks or failures over time.

- Corrosion and leaks: If electric flux paste is used on plumbing connections, there is a higher risk of corrosion and leaks in the long run. The lack of proper cleaning and bonding can result in the accumulation of moisture, causing corrosion to develop within the joint. Corrosion weakens the connection, making it more prone to leaks and potentially causing damage to the surrounding plumbing system.

- Compromised plumbing system: Ultimately, using electric flux paste on plumbing can compromise the overall integrity and performance of the plumbing system. Weak bonds, leaks, and corrosion can result in reduced water flow, decreased efficiency, and potential damage to the structure or surrounding areas.

Can you use electrical flux paste on metal plumbing pipes?

It is not recommended to use electrical flux paste on metal plumbing pipes, especially copper water pipes.

Electrical solder, including the flux it contains, is specifically formulated for soldering copper wires in electrical applications, and its flux may not be suitable or safe for plumbing purposes.

When soldering copper water pipes, it is essential to use a separate paste flux that is specifically made for sweating or soldering copper water pipes.

These fluxes are designed to clean the surfaces, remove oxidation, and provide proper bonding for plumbing connections. They are also formulated to meet safety and regulatory standards for potable water systems.

It is crucial to be aware of the composition of solders, as some electrical solders may contain lead or other materials that are not suitable for potable water systems.

When working with plumbing systems, it is advisable to use lead-free solders that comply with applicable plumbing codes and regulations.

To ensure proper and safe soldering of copper water pipes, always use a separate paste flux explicitly made for plumbing applications and select solders that are suitable for potable water systems and meet relevant regulations.

Other interesting articles: